Category Archives: Membrane modules

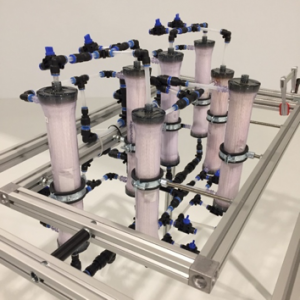

Compact forward osmosis membrane elements are ideal for piloting studies in industrial applications

When piloting FO membrane elements, high packing density, light-weight, ease-of-use, and flexibility are key advantages [...]

Jul

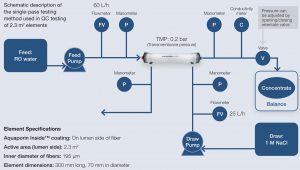

New forward osmosis hollow fiber element bridges the gap between lab-scale testing and industrial applications

Forward osmosis is one of many new water technologies addressing the growing need for sustainable [...]

Jul

Inquiry: FO membrane elements for pilot unit with 2 to 3 m3/h feed flow

Recently, we received an inquiry from Dr. Arcari (Customer Experience Supervisor Membrane) who is on [...]

1 Comment

Jun

Inquiry: forward osmosis elements needed for an FO/RO wastewater pilot plant

Commercial suppliers needed to provide FO modules for an FO pilot system Recently we received [...]

3 Comments

Mar

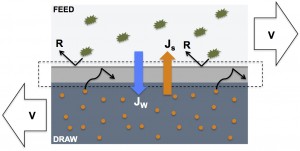

Inquiry: draw and feed circulation paths in FO modules

How do draw and feed streams circulate in an FO module? Most of us who [...]

Mar

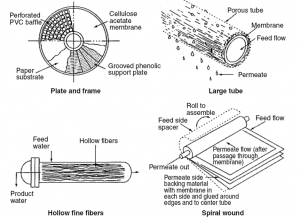

Hollow fiber forward osmosis membrane modules

Hollow fibre modules made from hollow fibre forward osmosis membranes Hollow fibre module summary Packing [...]

6 Comments

Mar

Spiral wound forward osmosis membrane modules

Spiral wound modules made from flat sheet forward osmosis membranes Spiral wound module summary Packing [...]

13 Comments

Mar

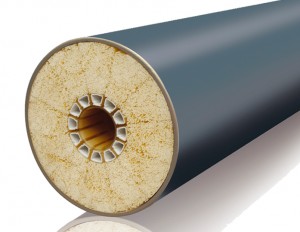

Tubular forward osmosis membrane modules

Tubular modules made from tubular forward osmosis membranes Tubular module summary Packing density Up to [...]

3 Comments

Mar

Plate and frame forward osmosis membrane modules

Plate & frame modules made from flat sheet forward osmosis membranes Plate & frame (stacked) [...]

9 Comments

Mar

The 4 different designs of forward osmosis (FO) membrane modules

An overview of the 4 different types of forward osmosis (FO) membrane modules FO membrane [...]

5 Comments

Mar