- Forward osmosis is not dead – interview with leading water consultant Walid Khoury - August 30, 2020

- Listing of major commercial & academic FO players on ForwardOsmosisTech - April 12, 2020

- 0.26MGD FO-SWRO Hybrid for seawater desalination achieves 25% energy reduction compared to MF/SWRO - December 14, 2019

The forward osmosis membrane hype

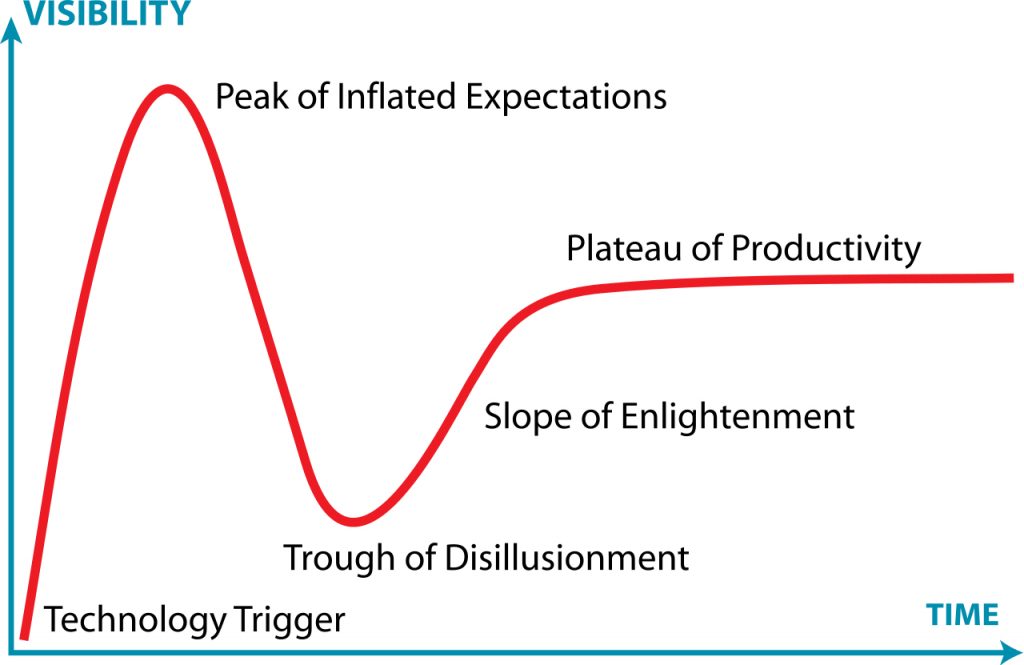

Jeffrey R. McCutcheon recently published the article “Avoiding the Hype in Developing Commercially Viable Desalination Technologies” – Joule 2019 – in which he describes how forward osmosis technologies – applied to desalination of seawater – have followed Garner’s hype circle and currently reside somewhere in the region between the “Trough of Disillusionment” and the “Slope of Enlightenment”.

It’s easy to understand why the desalination field, with its large membrane consumption and high energy costs, is prone to membrane technology hypes. It is all too tempting to extrapolate successful lab results – demonstrating superior water flow per energy input – into the next desalination revolution that will end worldwide water shortages. However, the fact remains that RO-based desalination is already extremely energy efficient and any new membrane technology offering orders of magnitude higher water flow will have a surprisingly little effect on overall energy consumption.

Adding to the dominant position of RO-based desalination, is the reality that, at the end of the day, any real market traction in the water treatment industry is critically dependent on real life operational data showing economic viability. We made this exact point close to 5 years ago in a response to McGovern and coworker’s article “On the potential of forward osmosis to energetically outperform reverse osmosis desalination”.

There’s no denying that, within the desalination field, RO membrane technologies have a 30-year head start of demonstrating real life economic viability.

Entering the “Slope of Enlightenment” for Forward Osmosis Technologies

It is fair to say, that the FO field took a hit and experienced some disillusionment when it became clear the technology would likely never revolutionize seawater desalination.

Instead of aiming to replace RO, surviving commercial FO players are now looking to occupy spaces where conventional RO is not applicable and where incumbent – and typically thermal based – technologies are much easier to beat.

Often, these spaces are found in food, beverage, and ingredients industries where water removal is an integral process step towards final products. Here, FO technologies promise gentle water removal resulting in higher quality end products.

Despite having identified spaces where a strong value proposition can be developed, it is fair to say that the FO field has yet to experience widespread commercial success. “Blockbuster” applications are needed and perhaps one such application is waiting to be unlocked within the booming industrial fermentation sector.

Could continuous removal of ethanol in fermentation liquids catapult FO onto the “Plateau of Productivity”?

Broadly speaking, fermentation is a microbial process by which microorganisms – often yeast – convert carbohydrates into desirable metabolic end products. Besides being used for food preservation (kimchi, miso, nato, etc.) and production of beer & wine, food companies are now utilizing fermentation in specially engineered microorganisms to answer an ever increasing demand for natural ingredients that are hard to come by. Ingredients such as resveratrol, stevia, vanillin, and even safron.

According to a market report by Persistence Market Research, the global fermented ingredients market will be worth US$ 40 billion by 2022. It is therefore not surprising that food manufacturers are currently intensifying their efforts to improve fermentation processes.

One obvious area of improvement is to continuously remove any ethanol that is produced as a byproduct in fermentation liquids. The removal serves to avoid ethanol’s inhibitory effect on microbial growth, which already kicks in at ethanol concentrations below 2% (20g/l) (see for example “Inhibition of Alcoholic Fermentation” by G. Moulin and coworkers). And this is where FO potentially offers a superior solution.

NineSigma recently published an RFP on continuous ethanol removal where FO was among the shortlisted technologies.

NineSigma is a global technology scouting agency; helping clients find innovative solutions through connections to a broad network of start-ups, SMEs and academia.

Recently, NineSigma published a request for proposal on behalf of a leading global food manufacturer seeking a technology to continuously remove ethanol produced as a byproduct in fermentation liquid.

Technology requirements as per NineSigma’s RFP:

- Alcohol can be continuously removed concurrently with reaction/fermentation process.

- Ethanol need not be collected, therefore approaches to degrade ethanol are acceptable as well as separation.

- Processing without changing the conditions of fermentation is possible. (See the reference value below.)

- Temperature: 25–35˚C

- pH: 5–7

- Gauge pressure: 0–120 kPa

- Osmotic pressure of the fermentation liquid: 500–800 mOsm

- The ethanol concentration can be maintained at 0.5% or lower.

- Ethanol production speed: about 1%/hour

- Ethanol concentration without any ethanol removal measures: 0.5–5.0%

- (In case a separation membrane or another material is used) Sterilization is possible, e.g. steam sterilization for 30 minutes at 120˚C, solvent sterilization, etc.

- The target product (most likely, low molecular weight organic compound, peptide, or protein) will not be lost. A process that the proposed technology will be applied to has not been specified and it will be determined depending on the separation capability of the proposed technology.

Designing an FO system to match the technology requirements

From a practical point of view, an FO system capable of continuously removing ethanol from fermentation liquid requires the following key components:

- Industrial scale, low-fouling, and sanitary FO membrane elements with high rejection to the target product, low reverse diffusion of draw solutes, and low – preferably zero – ethanol rejection.

- A suitable draw solution recovery system based on a food grade draw solute compatible with microbial growth.

- To avoid water wastage, an ethanol removal system (e.g. air stripper) on the draw side could potentially enable water recycling into the fermentation liquid.