- Nano-selective forward osmosis technology by SideStroem featured in Everything About Water - February 10, 2024

- SideStroem and Singapore Institute of Technology featured in AsianScientist - April 29, 2023

- SideStroem joins world class accelerator program - November 12, 2022

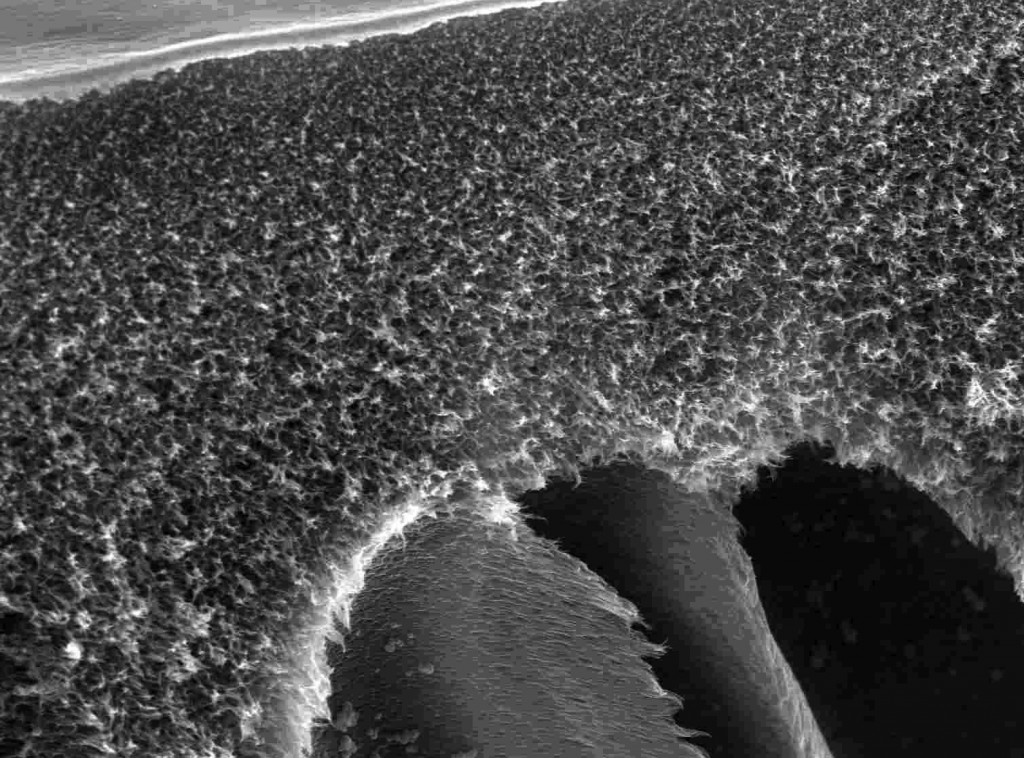

Asymmetric cellulose acetate and cellulose triacetate based forward osmosis membranes formed by phase inversion (both support membrane and active layer)

Before proceeding with the main content sections of this article, we would like to note that the information presented below is based – in part – on the excellent forward osmosis review article by Zhao et. al. (2012)

“Recent developments in forward osmosis: opportunities and challenges”, Zhao et. al. 2012

Asymmetric cellulose acetate and cellulose triacetate (CTA) membranes were some of the first polymeric membranes used by researchers in forward osmosis applications. And from a commercial point of view, a CTA based membrane was for a long time the only commercially available forward osmosis membrane product and is still produced and sold by Hydration Technology Innovations today.

One of the advantages of cellulosic membranes is that the support and active rejection layer are formed in the same process – phase inversion of a precursor dope solution followed by hot water annealing. In addition, cellulosic membranes are quite hydrophilic (i.e. good water flux performance and low propensity to fouling), have good mechanical strength, and membrane components are readily available commodities.

On the negative side, cellulosic membranes must be kept within a narrow operational window (pH 4-6 and temperature below 30° Celcius) in order to maintain operational integrity. This excludes cellulosic membranes from being used for treatment of harsh industrial waste waters.

When it comes to determining the performance characteristics of cellulose acetate or cellulose triacetate membranes forward osmosis membranes, research groups have directed their focus towards the CTA based membrane from HTI. Below is a short summary of some representative work. It is evident that the CTA membrane has some performance variation from batch to batch, or alternatively, that research groups have different ways of determining A, B, and S values.

| Research work | A (LMH/bar) | B (NaCl) (LMH) | S (μm) |

| Reverse draw solute permeation in forward osmosis: modelling and experiments, Philip et. al., 2010 | 0,44 | 0,265 | 481 |

| Influence of concentrative and dilutive internal concentration polarization on flux behaviour in forward osmosis, McCutcheon et. al., 2006 | N.A. | N.A. | 360 |

| Nano gives the answer: breaking the bottleneck of internal concentration polarization with a nanofiber composite forward osmosis membrane for a high water production rate, Song et. al., 2011 | 0,39 | 0,57 | 620 |

Thin film composite polyamide-based forward osmosis membranes formed by phase-inversion (support membrane) and interfacial polymerization (active layer)

Recently, polyamide-based thin film composite (TFC) membranes have been prepared for forward osmosis applications. TFC membrane formation is a two-step process. First a support membrane, typically composed mainly of polyethersulfone, is formed by phase inversion of precursor dope solution. Next, a thin (around 200nm) polymeric rejection layer is formed on top of the support membrane by interfacial polymerization of m-phenylenediamine (MPD) and trimesoyl chloride (TMC). A similar process has been used since the 1990ies to produce RO membranes. The difference between TFC FO and TFC RO membranes lies mainly is the support substrate, which for FO membranes is considerably more porous, more hydrophilic, and thinner.

Thin film composite forward osmosis membranes have several advantages over cellulosic FO membranes:

- Support higher working temperatures (in excess of 60° Celcius)

- Increased tolerance towards pH (pH range of 2-11 is tolerated)

- Higher A-values

The advantages of TFC membranes make them the preferred design for commercial forward osmosis membranes. However, due to the two-step process and the inherent difficulties in controlling the interfacial polymerization, TFC membranes are more expensive to produce than their cellulosic counterparts.

Below is a short summary of TFC forward osmosis membrane performances reported in literature.

| Research work | A (LMH/bar) | B (NaCl) (LMH) | S (μm) |

| Relating performance of thin-film composite forward osmosis membranes to support layer formation and structure, Tirraferri et. al., 2011 | 1,90 | 0,33 | 312 |

| Nano gives the answer: breaking the bottleneck of internal concentration polarization with a nanofiber composite forward osmosis membrane for a high water production rate, Song et. al., 2011 | 1,25 | 0,49 | 450 |

Thin film composite polyamide-based forward osmosis membranes based on electrospun nanofiber webs (support membrane) and interfacial polymerization (active layer)

Researchers have investigated different strategies for creating support membranes with smaller structural parameter values to reduce the negative effects of concentration polarization on forward osmosis performance. One promising strategy is to replace the traditional phase inverted polyethersulfone-based support membrane with a support membrane consisting of a thin polyethersulfone nanofiber web coupled to a poly (ethylene terephthalate) (PET) nonwowen substrate. Here, the nanofiber web provides a suitable interphase for interfacial polymerization and the PET substrate provides mechanical strength. With this approach, researchers have achieved structural parameters as low as 80µm.

| Research work | A (LMH/bar) | B (NaCl) (LMH) | S (μm) |

| Nano gives the answer: breaking the bottleneck of internal concentration polarization with a nanofiber composite forward osmosis membrane for a high water production rate, Song et. al., 2011 | 1,70 | 1,17 | 80 |

Thin film composite polyelectrolyte-based forward osmosis membranes formed by phase-inversion (support membrane) and layer-by-layer deposition (active layer)

In some applications, forward osmosis membranes with low rejection to NaCl outperform traditional high rejection membranes. In a sense, the trade-offs between low and high NaCl rejection FO membranes can be compared to the trade-offs between pressure-driven NF and RO membranes. Here, the larger pore diameter in the active layer of NF membranes yields higher water flux performance at the expense of lower rejection towards small solutes such as NaCl.

Low NaCl rejection forward osmosis membranes can be used in applications where the NaCl content of feed and draw streams is negligible or alternatively where it is advantageous to have NaCl pass across the membrane.

Within the last couple of years, researchers have utilized layer-by-layer deposition of oppositely charged polyelectrolytes to form selective layers with larger pore diameters. As shown in the brief summary below, A-values of polyelectrolyte-based forward osmosis membranes can exceed high NaCl rejection membranes by a factor 3-4.

| Research work | A (LMH/bar) | B (MgCl2) (LMH) | S (μm) |

| Synthesis of high flux forward osmosis membranes by chemically cross linked layer-by-layer polyelectrolytes, Qiu et. al., 2011 | 6,9 | 0,92 | N.A. |

Notes: Post thumbnail taken from http://permeant.cee.duke.edu/projects/project3.html