- Nano-selective forward osmosis technology by SideStroem featured in Everything About Water - February 10, 2024

- SideStroem and Singapore Institute of Technology featured in AsianScientist - April 29, 2023

- SideStroem joins world class accelerator program - November 12, 2022

What is hemodialysis?

The human kidneys carry out a range of life essential functions:

- Excretion of waste molecules

- Regulation of the water and salt balance

- Regulation of the blood’s acidity level

- Regulation of blood pressure

- Prevention of bone decalcification

- Regulation of blood percentage

Kidney diseases reduce these functions leading to a gradual build-up of waste molecules and water in the body. For end stage renal disease (ESRD) patients there are currently two treatment methods:

- Transplantation: live and deceased donor kidneys

- Dialysis: hemodialysis (90% of dialysis treatments) or peritoneal dialysis (10%)

Hemodialysis is a treatment where a hemodialysis machine uses an artificial kidney coupled to the blood stream to:

- Remove waste molecules

- Remove water

- Regulate salts and blood acidity

- Prevent bone decalcification

- Intravenously administer EPO and iron supplements to maintain blood percentage.

In essence, the hemodialysis machine is composed of tubular ultrafiltration membranes (typically polysulfone-based) with well-defined molecular weight cut-offs (MWCO’s) that allow water, salts, and waste molecules to pass through while at the same time retaining blood within the lumen of the tubes.

Patients typically require hemodialysis treatment 3 times a week with a duration of 3-5 hours per treatment. Today, a treatment of 4 hours requires around 120 liters of highly purified water. The purified water is produced by means of reverse osmosis in dedicated high-volume purified water treatment system (for dialysis centers) or in smaller water treatment systems (for home dialysis).

Home dialysis increases quality of life but adoption is low

In comparison to in-center treatment, home dialysis is more convenient, results in shorter recovery times, and enables tailored therapy. Globally, though, home dialysis has a low adoption rate with only 1% of patients receiving treatment at home. Despite policy makers looking to increase the uptake of home dialysis – in the US alone there’s a push for 80% of patients receiving home dialysis or kidney transplants by 2025 – the complexity and size of dialysis machines present a major barrier to home use. Innovations towards simplified design & reduced machine size will undoubtedly increase the uptake of home dialysis.

The market potential for membrane-based water treatment solutions within hemodialysis

According to the “Global Market Analysis, Insights and Forecast, 2018-2025” report from Fortune Business Insights, the global hemodialysis equipment market is anticipated to be worth US$ 16,321.6 Mn by 2026 with an annual CAGR of 4.5%.

It is estimated that more than 3 million people worldwide suffer from end stage renal disease and therefore require regular dialysis treatment.

In order to arrive at an estimate of the market potential for membrane-based water treatment solutions within the hemodialysis equipment market, one must first estimate the number of hemodialysis machines worldwide.

Based on an assumption that hemodialysis machines are in operation on average 8 hours per day, 7 days per week, and that 3 million ESDR patients worldwide require 12 hours of weekly hemodialysis (3 treatments of 4 hour duration), approximately 643,000 hemodialysis machines are needed to provide the necessary treatment capacity.

Since each hemodialysis machine requires 30 litres of purified water per hour (or 0.5 litres per minute) the water requirements can – in principle – be met on an individual machine level through compact reverse osmosis elements. As an example, compact 3012 (3.0 inch diameter, 12 inch length) RO elements are capable of delivering 300-600GPD (or 0.8 – 1.6 litre per minute) permeate flow, which – on paper – is more than sufficient to meet the water requirements of a hemodialysis machine.

Typically, compact RO elements for water purification are replaced every 6 months, hence in this back-of-the-envelope calculation, the total global annual membrane demand for hemodialysis is estimated at 1.286 million 3012 300-600GPD RO elements. This corresponds to a market potential in excess of 100 million USD.

How can forward osmosis improve hemodialysis?

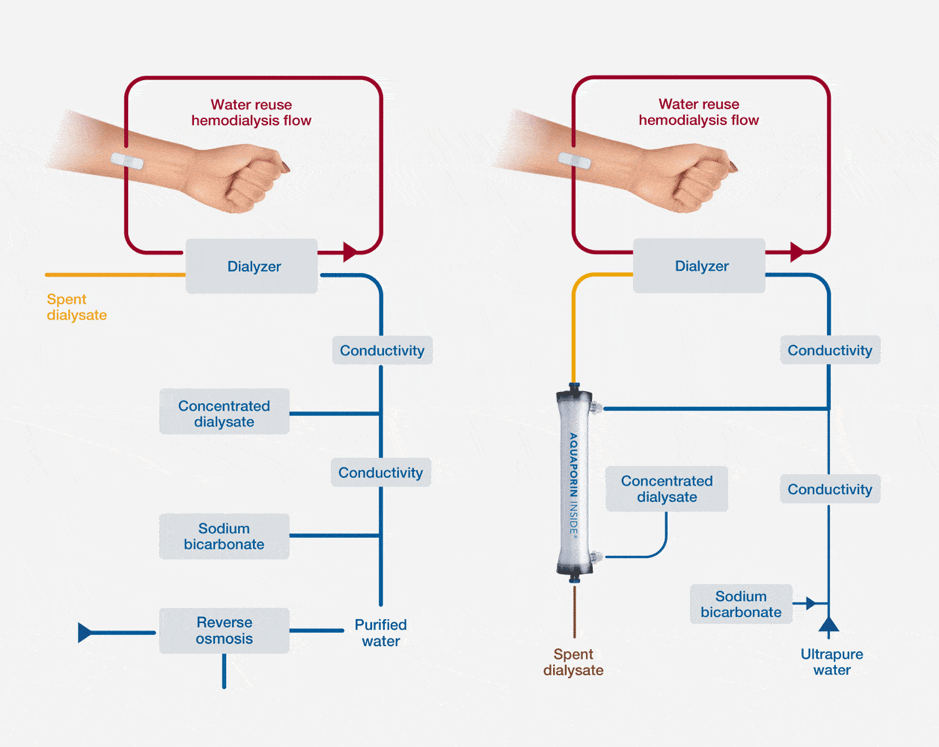

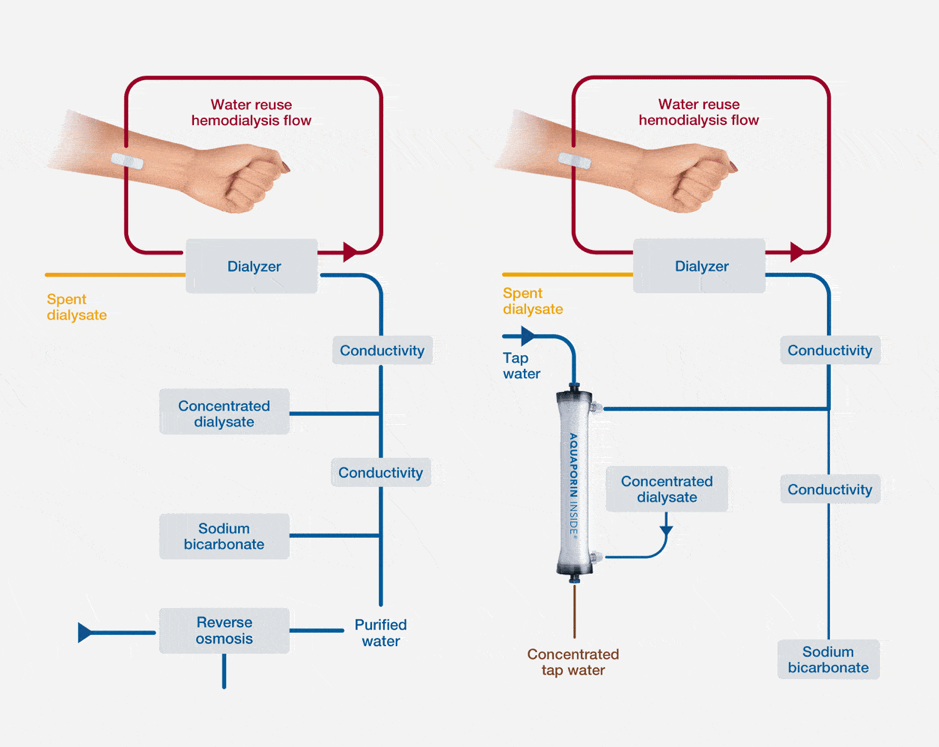

In conventional hemodialysis, reverse osmosis systems are used to produce the purified water needed to dilute the concentrated dialysate fluid and sodium bicarbonate. After dilution, the dialysate fluid is ready to be used for the treatment process and enters the dialyzer where it facilitates the removal of waste molecules, water as well as regulation of salts and blood acidity. The spent dialysate fluid – containing all the waste molecules from the patient – is discarded directly to the drain.

Forward osmosis systems utilize the osmotic pressure of the concentrated dialysate fluid and sodium bicarbonate to extract pure water from the spent dialysate fluid with the following key benefits:

- Reducing the pure water demands in dialysis centers by up to 75% ® resulting in tangible cost savings.

- Eliminating the need for separate RO-based water treatment system for home dialysis machines, thus, enabling a reduced size and energy footprint of the water treatment system and, thus, making the entire home dialysis machine smaller, lighter, and more portable.

In order to be applicable for dialysis processes, it is essential that the selected forward osmosis membrane technology has exceedingly high rejection values towards all waste molecules in the spent dialysate fluid. If not, the resulting dialysate fluid will be contaminated during the forward osmosis process rendering it incompatible with patient use.

Case study: hemodialysis solutions incorporating the Aquaporin Inside® Forward Osmosis technology

The Danish water-tech company Aquaporin has developed Aquaporin Inside® hollow fiber forward osmosis (FO) biomimetic membranes with ultra-high rejection values towards a wide range of contaminants. The company is actively pursuing the use of its proprietary forward osmosis membrane technology on for improvement of both in-center and home dialysis processes as outlined in the figures below.

According to Esben Gad, Vice President Business Development, Aquaporin’s Forward Osmosis technology is mature and ready to be implemented into the hemodialysis process: “Aquaporin has proven the forward osmosis water reuse concept with clinical fluids, lifetime studies and economic modelling. The next step is to take the solution into clinical development together with a partner in the dialysis industry.”

How to get involved?

The hemodialysis team at Aquaporin is actively pursuing co-development agreements with leading medical device companies. Please reach out via Aquaporin’s contact form if you’re interested to learn more about available collaboration opportunities, you can also learn more at aquaporin.com/hemodialysis.